Diamond Edge Polisher

Model: ZT-1800

Product Description:

A. Can be polishing 80mm (max) thickness materials,

length is unlimited.

B.

Adopted imported diamond blades, better polishing effect and

longer lifespan.

C.

2Pcs of roughing blades, 1Pcs of finishing blade, 3 blades

ensure high speed and high precision.

D. Adopted Mitsubishi belt from Japan, SKF

Bearings from Swiss, mechanical spring from Germany.

E. Imported Spindle & Inverter, ensure high speed, high

precision & high stability.

F.

Dual-motor driving/dual-belt synch-feeding, it can avoid

staggered problem while polishing many pieces sheets together.

G.

The platform length extends to 1.8M, polishing long

panel sheets feeding is more easy and stable.

H. One side pulley height adjustable, it can avoid

feeding direction not completely parallel with guide rail

problem.

I.

New concept of cutting hub design, it can prevent

blades broken

J.

Polishing thickness auto compensation, it can continue

polishing different thickness of materials, maximum thickness

tolerance is 6mm.

K.

New vortex pump for vacuum suction, higher pressure radio, low

noise and lower energy consumption, maintenance-free.

L.

Integrated vacuum dust tank,

filter net is added to the vacuum dust collector tank,

it can better extracted the plastic swarf from the machine.

M.

Equipped with industrial water chiller, better cooling effect

for the spindle motor

PMMA Edge Polisher/Acrylic Edge Polisher/Plastic Edge Polisher

Product Features:

(1).

Can be polishing Acrylic, Organic Glass, PMMA, PC (poly C), PS board,

etc°≠

(2).

High efficiency, one machine working more than 30 traditional

workers.

(3).

High quality polishing, after polished by diamond polishing

machine, the surfaces are smooth like mirror, no bubble or other

deficiency caused by traditional cloth wheel or flame polishing.

It is an essential machine for processing high-class

acrylic/organic glass/crystal/PC/PS board products.

(4). High precision, low labor cost, no material waste,

but perfect polishing finish

(5). Equipped with high power dust collector, no dust or

splash during polishing.

(6). Safety and easy to use, automatic polishing by

machine, reduce labor injury.

(7). Environment friendly, no powder, low noise and low

energy.

(8). CE Certificated.

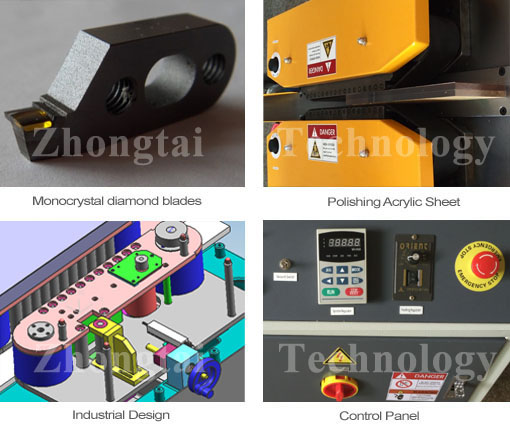

Parts of machines:

ZT-1800 Diamond Edge Polisher Assemble Line:

Samples:

°°

Detailed parameter:

|

Model |

ZT-1800 Diamond Edge Polisher |

|

Maximum cutting length |

Unlimited |

|

Maximum Cutting width |

80(mm) |

|

Cutting mode |

End surface cutting |

|

Cutting Angle |

90 Straight line |

|

Cutting Depth |

0~0.5mm (adjustable) |

|

Cutting Speed |

>1000mm/min (Suggest 600mm/min) |

|

Spindle Speed |

6600~11000 RPM |

|

Spindle Motor |

4KW |

| Spindle End Pulsation |

°‹0.01MM |

| Work table of motion straightness error |

°‹0.05MM |

|

Fixed Material mode |

Manual Crank handle |

|

Diamond Tools |

2Pcs PCD blade, 1Pcs Monocrystal blade |

|

Dust Collector |

1.1 KW |

|

Dust Collector interface |

50mm |

|

Machine Dimensions |

1850x750x950 mm |

|

Input Power |

220V, Single Phrase or 380V, 3Phase |

|

Rated Power |

5.5KW (actual use 2KW) |

|

Weight |

320 KG |

|

Consumable Parts |

Blades |

°°